The demand for efficiency is rapidly growing for businesses, leading many company leaders to adopt physical automation (robotics) into their processes industries, from warehousing to agriculture, cleaning, and more.

However, simply adopting robots doesn’t instantly increase efficiency. Technical issues, human error, and unforeseen circumstances can all affect a robot’s performance and, ultimately, the bottom line.

Any moment a robot is down when they’re expected to perform a task, end-users lose money. Should this happen often, overall efficiency quickly plummets and causes significant financial losses down the line when goals go unmet. However, the repercussions of downtime aren’t limited to only finances; end-users lose time trying to correct issues, which can affect morale and take time away from improving other processes.

Although the actual cost of robot downtime is unique to each company, let’s dive into how downtime truly affects automation efforts and how to prevent it.

What is robot downtime?

First, let’s briefly review the definition of robot downtime and its types. Robot downtime is the opposite of uptime, meaning downtime is any moment when the robot is not performing a task.

There are two types of robot downtime: planned and unplanned. Planned downtime is factored into the overall costs of adopting physical automation and includes preventative maintenance cycles, upgrading robot equipment, and upskilling or training workers on the machines.

Unplanned downtime is much more detrimental. Causes of unplanned occasions are reactive, with catalysts running from device failure to staffing issues and significant events such as a power outage. Regarding manufacturing, experts say unplanned production downtimes can cost 15 times more than planned production downtimes, which has similar impacts in environments outside warehouses.

Calculating the cost

Solid numbers cannot be applied across industries, but manufacturing is one where the cost of downtime has been extensively observed. Industry experts caution about the potential costs of robot downtime, estimating a substantial range from $1,000 to an imposing $10,000 per minute.

Although the numbers may not be exact in an agricultural or healthcare setting, for example, the longer the robot is offline, the more other processes are affected. Beyond the immediate financial losses, there are operational disruption cost impacts to consider. Unplanned downtime disrupts the rhythm of other tasks, leading to inefficiencies, delays in project timelines, and potential penalties for missed deadlines. Factoring in these disruptions provides a more holistic and consequential view of the overall impact downtime causes.

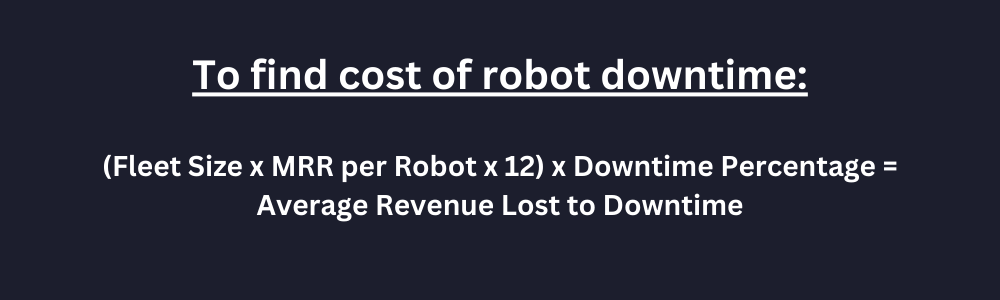

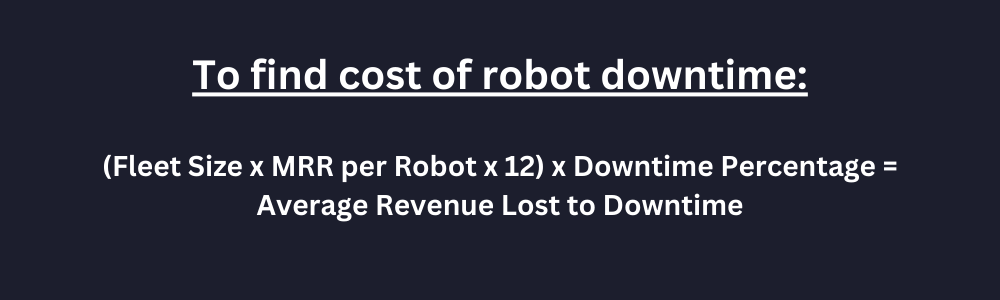

Calculating the exact cost of downtime is difficult, but there is an equation to follow that can provide a general idea of cost loss.

Take the size of the fleet (say 1,000 cleaning robots) and multiply it by the “MRR per robot” (let's say $1,500), then multiply this by 12 months to find the total amount of revenue driven from your fleet per year. Then, multiply that by your average robot downtime (or subtract your uptime number from 100%) to understand how much potential revenue was lost in downtime for the year.

Of course, there are other variables that may affect revenue, but this calculation should provide a general overview. If you’re interested in understanding the aggregate ROI of your fleet, reach out to our team for an ROI assessment of your fleet.

Unplanned downtime can also decrease the chances of scaling beyond current numbers. Most companies' continuing goal is to grow robot fleets as their customer base grows. However, if downtime occurs often and isn’t being actively prevented, customers lose trust in more automation and stay at more manageable fleet numbers or churn altogether.

Monitoring & preventing robot downtime

The good news is that although some downtime is inevitable, most unplanned downtime can be prevented with the right tools in place.

Securing a cloud robotics platform, like Formant, is the first step toward managing downtime. On a platform, data is captured from robots and sensors, allowing end-users to analyze against operational metrics, such as uptime, and highlight anomalies and trends. These insights can then inform process improvements and proactive maintenance schedules that are turned into event-triggered workflows so users can improve their preventative efforts and uptime.

Some of these downtime-related processes a platform informs include:

- Eliminating unplanned downtime and improving overall equipment effectiveness (OEE) with proactive service.

- Alerting teams when sensitive machine components hit critical conditions.

- Understanding mean time to failure and determining accurate service timelines.

- Determining the right time to invest in hardware system upgrades.

The above insights allow errors and unplanned maintenance to be significantly reduced and even predicted.

Of course, there are other factors that cause downtime a platform cannot prevent or monitor, including power outages/other major weather events, human error, or massive damage to a system. In these situations, encourage customers to have a plan in place with their staff to get robots back up and running as soon as possible, checking for any damage or errors that need to be addressed first after a significant event. Developing reactive plans won’t prevent issues outside of the vendor’s control, but they’ll at least help minimize robot downtime as much as possible.

Understanding the cost of robot downtime is complex and includes more than just revenue in terms of losses. Downtime affects staff, customers, and the business’s overall bottom line. With a suitable cloud robotics platform and data-first approach to improving robot operations, it's possible to reduce robot downtime, increase revenue, and further improve the robot’s ROI.