Teleoperation

What is teleoperation

The demand for efficiency is rapidly growing for businesses, leading many company leaders to adopt physical automation (robotics) into their processes industries, from warehousing to agriculture, cleaning, and more.

However, simply adopting robots doesn’t instantly increase efficiency. Technical issues, human error, and unforeseen circumstances can all affect a robot’s performance and, ultimately, the bottom line.

Any moment a robot is down when they’re expected to perform a task, end-users lose money. Should this happen often, overall efficiency quickly plummets and causes significant financial losses down the line when goals go unmet. However, the repercussions of downtime aren’t limited to only finances; end-users lose time trying to correct issues, which can affect morale and take time away from improving other processes.

Although the actual cost of robot downtime is unique to each company, let’s dive into how downtime truly affects automation efforts and how to prevent it.

How does teleoperation work?

A teleoperation system consists of two parts. It includes a telemanipulator that a human operator controls at a distance and a robotic device. The human operator uses the telemanipulator to send signals to the robotic device via Wi-Fi, Bluetooth, radio signals, or other connections. The robotic device then carries out the functions.

What are the benefits of using teleoperation?

There is a wide range of benefits for teleoperation, and they include:

- Increased safety for human workers

- Ability to explore unknown or dangerous environments

- Cost-savings

- Increased productivity

Examples of Teleoperated Robots

There are a variety of applications for teleoperation in robotics. Some of the most popular use cases include:

- Remotely operated vehicles (ROV): It is the ability to drive or assist in operating the vehicle remotely. A typical example is a self-driving car.

- Remote surgery: This is when a surgeon can complete an operation on a patient without being in the same physical location.

- Uncrewed aerial vehicles: Often referred to as drones, this is an aircraft that flies without the physical presence of a human pilot, crew, or passengers. It is also known as a remotely piloted aircraft (RPA).

- Bomb disposal robots: These teleoperated robots disable explosive devices while remotely controlled by a human operator at a distance.

- Manufacturing machinery: These robotic devices can build automobiles, operate in a foundry, palletize consumer goods, and more.

The future of teleoperation

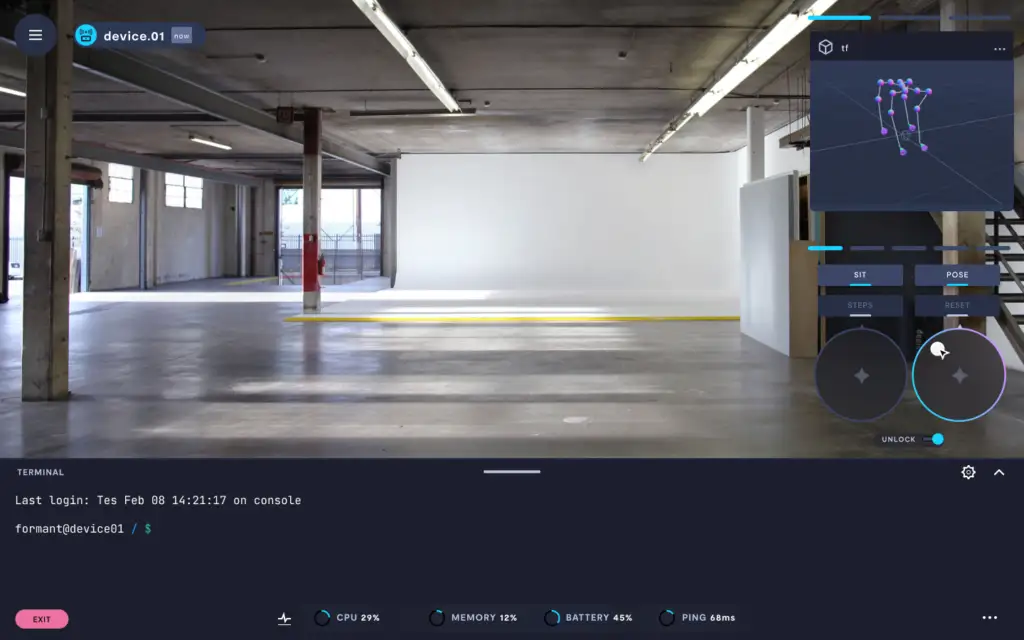

The world of teleoperation is shrinking when it comes to the telemanipulator. What was once massive, complex systems that required an advanced engineering degree to operate can now be found in your smartphone. The simplification of the telemanipulator device is making it possible for teleoperation to reach a wider audience. For example, with just a few taps of their phone screen, participants around the world were able to teleoperate Boston Dynamics’ robotic dog, Spot, on the streets of San Francisco.

Another discipline that is impacting the future of teleoperation is the evolution of virtual reality (VR). It opens up a world where human operators can remotely access and control machinery using a virtual reality system like an HTC Vive headset and hand controls. This allows an operator to teleoperate robots from their own home rather than in a factory setting.