How Hullbot is defining next-generation robotic hull cleaning

Hullbot has developed all elements of the platform’s software and hardware in-house and has unique capabilities in inspection, mapping, and interaction with submerged structures.

The company has been operating fleets of robots in paid pilots in Sydney and has proven a 15% fuel reduction on fleets of ferries with greeted gains expected in 2024. This is significant because the drag increase from biofouling on hulls accounts for >1% of global GHG emissions. Not only are existing solutions harmful to the ocean, they are only partially effective and most hulls have significant fouling year round. Biofouling is also a major threat to biodiversity because organisms are transferred to new environments and can destabilize ecosystems.

The challenge

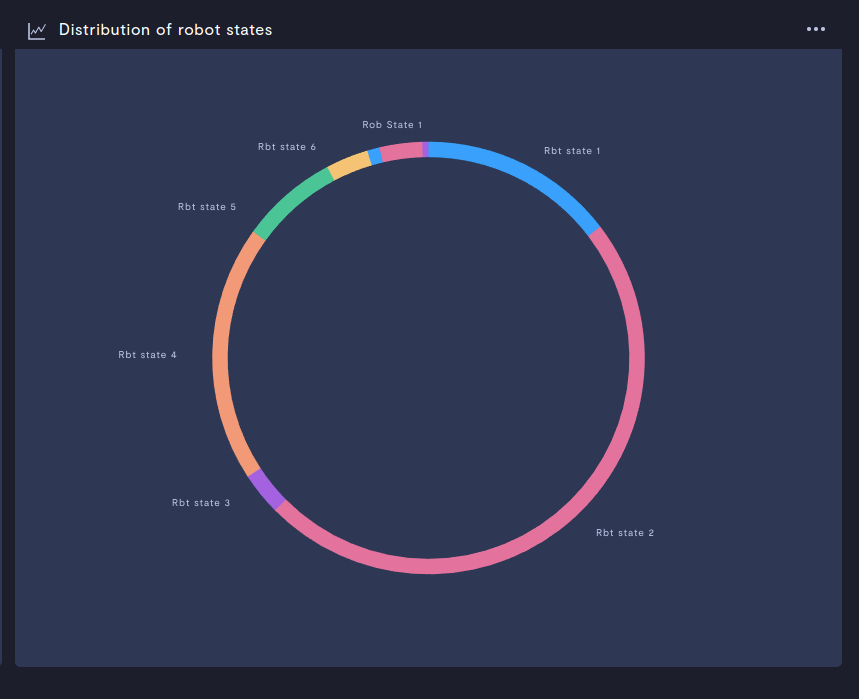

To support their fleet of robots, which are active with customers every day, Hullbot built internal data storage and review systems, as well as a rudimentary teleoperation pipeline. These tools interrogate hardware and software in real-time and deploy performance reports for customers. However, after building these systems, the team quickly realized there were a few large issues that would impact future scalability. First, they were spending too much time maintaining the system compared to the robot itself, as the systems didn’t allow for quick changes to the UI, and it wasn’t readily used by other functions outside of the R&D team. Actively expanding internationally, the Hullbot team knew they would need a platform that could handle multiple types of data and offer a variety of ways to review or visualize data points to produce insight across the business and for their customers. Rather than relying on robot and software engineers to review data, they needed a system to enable anyone to review in a way that suited their needs.

A smooth transition to new systems

A top priority for Hullbot was finding a system that would allow for an easy transition, especially to reduce development time and time to impact. With deployments and demos planned, the transition to a new platform needed to be easy and relatively quick to avoid any disruptions to underwater operations.

Flexible, scalable data-powered platform

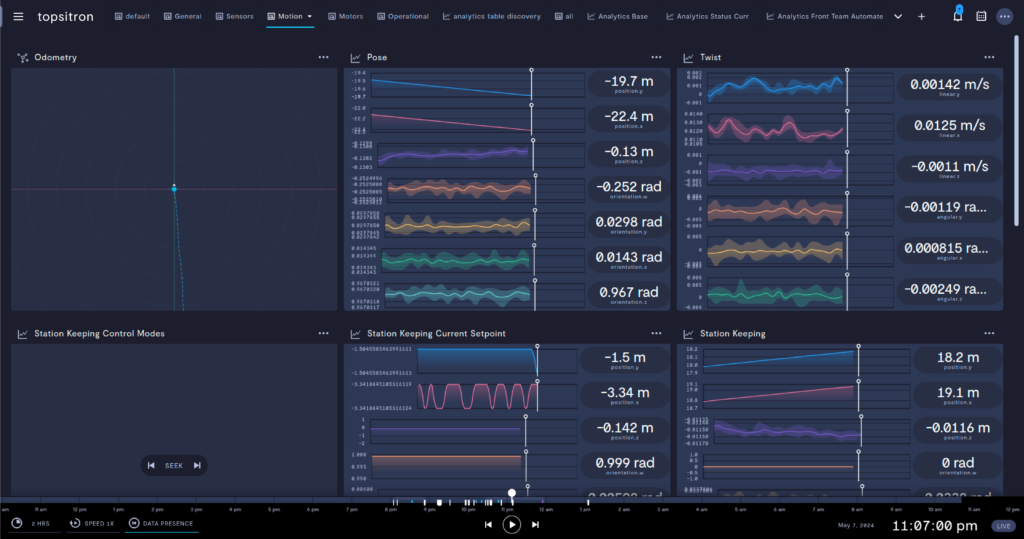

With their internal systems, data was collected from the robots, transferred into the custom database, transformed, and then piped to different tools for review or manipulation. The robot contains many sensors, an advanced underwater vision system and a powerful computing stack with most processing occurring on the robot. It is then tethered to a topside unit which can supply power and data and can be deployed and retracted from the water by a pod with multiple actuators and communication systems. To gather valuable data from the robot and pod, the team needed a platform to pipe all data securely for future visualization, continuous improvement, and customer insight.

Teleoperation for robots anywhere

Part of Hullbot’s vision for expansion involves establishing operations in multiple ports and hubs and ultimately sending robots to service ships all over the world. To achieve this, the ability to teleobserve, schedule, and operate from anywhere in the world to deploy robots for hull cleaning was non-negotiable. This also allows their team of remote operators to intervene without significant delay in cases if a robot experiences an issue.

The solution

Formant’s platform and teleoperation capabilities enable Hullbot’s team, in any department, to ingest all data from every device and teleoperate from anywhere, globally.

As Hullbot looks to future scaling efforts, Formant’s cloud platform assists them in making improvements to their robot and supports robot deployments on a variety of ships, unlocking a $175B market.

Easily navigated UI

The internal platform Hullbot’s engineering team built was just enough to achieve user requirements from an engineering perspective but difficult to navigate for those in other roles across the business. The partnership between Formant and Hullbot was valuable to both teams. Hullbot was able to quickly transfer their fleet to the platform, supported by Formant with a UI that can be easily utilized across any role to view, schedule, and gain insight into the performance of their robot fleet.

“We’re thrilled to be working with Formant. Not only are we saving time compared to our previous internal platform, we’re getting real value from their existing tools and are excited about collaborating to push the boundaries of what’s possible with their platform.”

Tom Loefler- CEO, Hullbot

Reliable teleoperation

As the fleet has grown, their internal teleoperation pipeline couldn’t keep up with the changes needed, and the operating team needed a reliable system to deploy the robots for cleaning tasks across the world. Now, they’ll deploy the robot via Formant’s teleobservation and teleoperation capabilities to complete its task in any body of water with a strong, low-latency connection from any location.

A scalable solution

To support future fleet growth plans, they needed a system that could keep up with each specific robot’s requirements. The robots are expected to be deployed in locations all over the world with growing hardware variants and differing maintenance, operation, and servicing pipelines. Now, Hullbot can ensure they have a strong data pipeline to support hardware improvements, gain insight, and scale their deployed fleet everywhere.

The outcome

A flexible, scalable cloud robotics platform to support worldwide hull cleaning, inspection and marine autonomy for a healthier future in our oceans.

By leveraging Formant’s cloud-based platform, Hullbot was able to overcome the limitations of the internally built systems and gain a user-friendly interface usable across the business globally. In recent pilot deployments, the team achieved validation of a 21% fuel savings and has secured multiple contracts with major ferry operators. With Formant, Hullbot is empowered to efficiently manage its growing fleet, optimize robot performance, and protect all marine life across the oceans.