BP is improving safety and efficiency by using robotics to inspect offshore sites remotely.

The challenge

Free employees from dangerous tasks

The simplest tasks, conducting rounds or analyzing a leak in a hard-to-reach location, are inherently more complicated on an offshore rig. Leveraging robotic technology to remove some of the danger from mundane tasks or conduct more in-depth investigations can dramatically improve the safety of employees.

Identifying problems and abnormalities earlier

The simplest tasks, conducting rounds or analyzing a leak in a hard-to-reach location, are inherently more complicated on an offshore rig. Leveraging robotic technology to remove some of the danger from mundane tasks or conduct more in-depth investigations can dramatically improve the safety of employees.

Improve the efficiency of remote sites

The simplest tasks, conducting rounds or analyzing a leak in a hard-to-reach location, are inherently more complicated on an offshore rig.

The solution

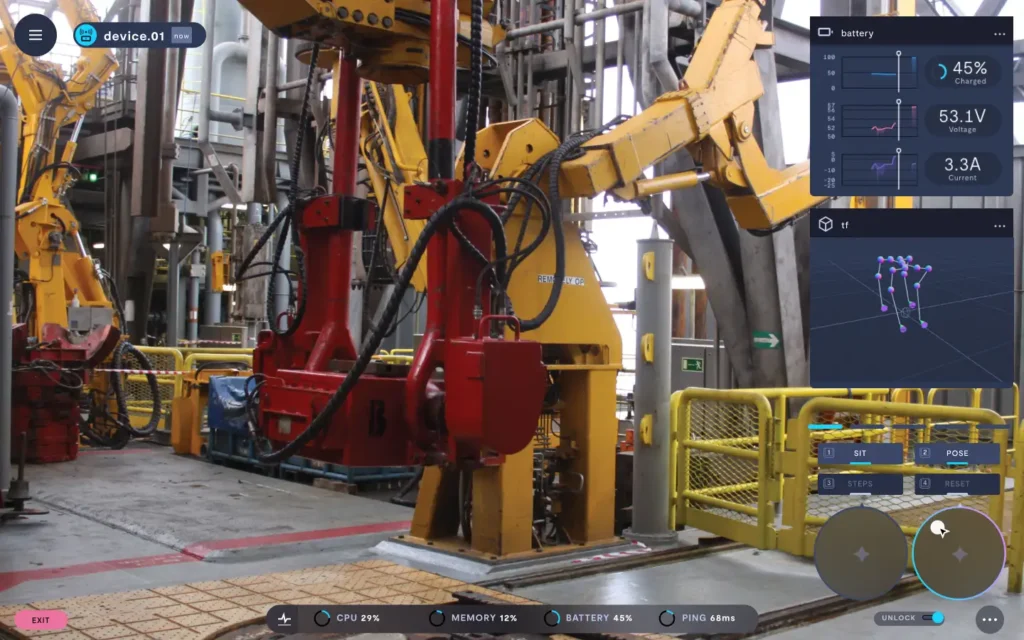

Remote command and control of Spot

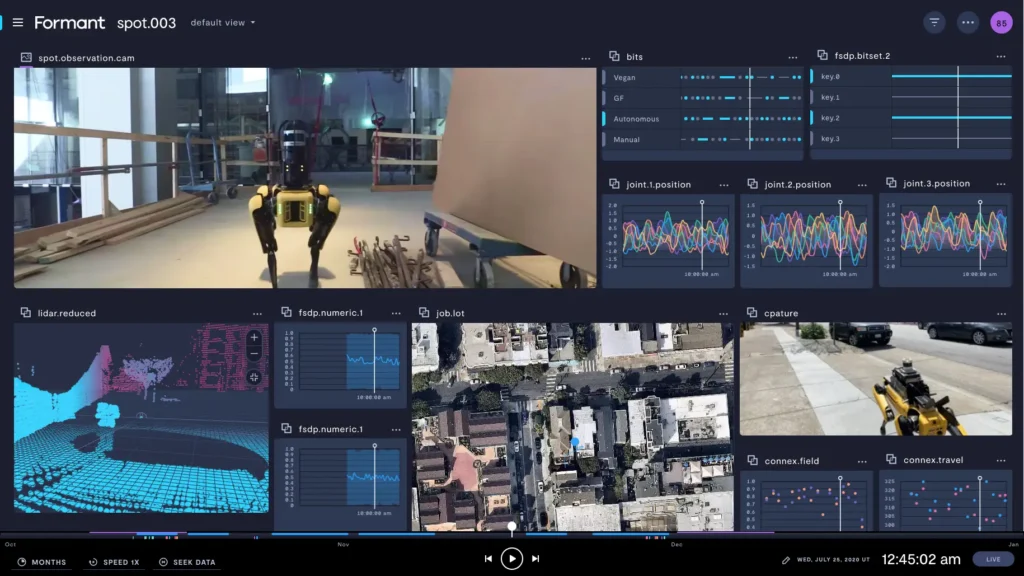

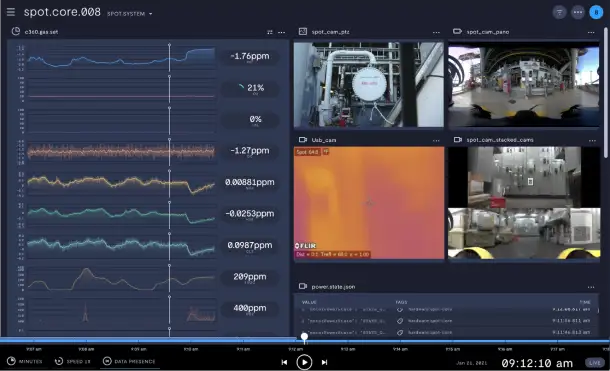

The Formant data and operations platform allowed BP to maximize the value of their investment in Spot by removing the need to have an employee directly operate it from just a few feet away. Formant remote operations also provided BP with economies of scale, allowing one operator to inspect and manage robots in a number of locations. The operator can control the PTZ camera on Spot to zoom in and read gauges, inspect corrosion, and inspect and quantify potential leaks. Formant also collects the data from additional sensors added to Spot, like methane levels, providing a comprehensive view of the environment and providing valuable contextual data to assist in diagnosing and remediating issues fou

Yasser Bangash — Robotics Technology Lead at BP

Remote collection and review of data

Centralizing domain expertise while having access to detailed inspection data from many remote sites provides BP a new level of operational efficiency. BP uses Formant to collect, consolidate, and visualize all the data obtained during an inspection in a single dashboard. Formant ingests the robot telemetry, video, audio, as well as any data that comes from additional sensors mounted on Spot, such as methane detectors, thermal, infrared, ultraviolet, & hyperspectral data. Viewing all data feeds together, in context, enables operators to compare data that would not normally be contained in a single location. Formant’s timeline navigation provides a simple and easy way to review and dive into particular moments of interest, even tagging an event to share with team member

Remotely diagnose and optimize onsite visits

A critical aspect of BPs solution is the ability to remotely review inspection and investigation data collected to proactively diagnostics and root-cause issues and events. Having all inspection data available for remote review empowers the operations team to be as prepared as possible prior to arriving on site. They can ensure they bring any parts or expertise required to address the issues. By having this data before they initially deploy, they are eliminating steps, and possibly multiple onsite visits, that add to the costs and carbon footprint to maintaining these offshore sites

Yasser Bangash — Robotics Technology Lead at BP