The future of automation isn’t just about deploying robots—it’s about managing them effectively. Yet, as companies scale their robotic operations, they often encounter a hidden roadblock: the complexity of multi-vendor robotics management —especially when different vendors, systems, and data formats are involved.

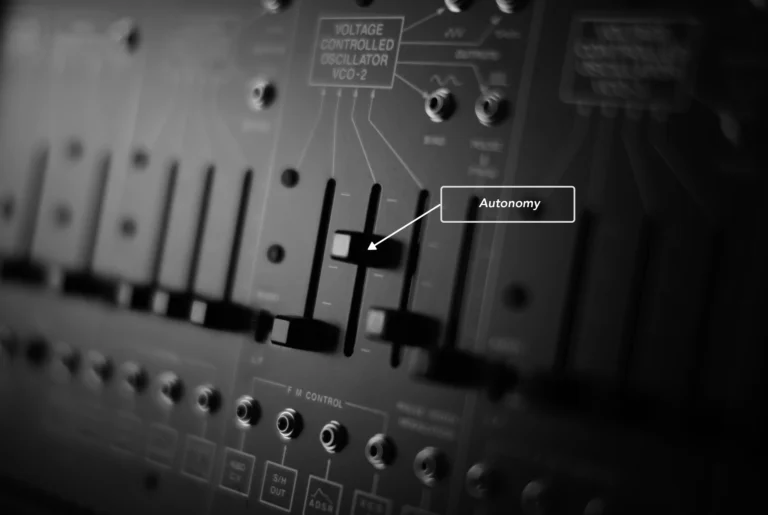

Operational leaders must balance scaling automation while ensuring seamless performance, minimal downtime, and maximum ROI. The key to success? Simplification.

From fragmented data to workflow inefficiencies, these challenges prevent businesses from fully realizing the potential of their multi-vendor robot fleet. So, how can operational leaders ensure seamless automation without getting trapped in a web of disconnected systems and siloed insights?

In this two-part series, we’ll explore the real-world challenges of how to manage a multi-vendor robot fleet—and, more importantly, how industry leaders are solving them.

The three major complexities of multi-vendor robotics management

1. Siloed Data is Limiting Operational Visibility

When businesses deploy robots and physical AI from different manufacturers, they often find themselves managing a patchwork of disconnected data sources. Without a centralized robot management platform, operational teams must navigate:

- Inconsistent performance metrics across different robot types

- Manual data aggregation that slows decision-making

- A lack of predictive insights, leading to unexpected downtime

What You Can Do: Operational leaders must look beyond individual robot dashboards and invest in AI-powered data unification to monitor their fleets in real-time.

2. Disjointed Workflows are Slowing Down Automation

Scaling robotic operations doesn’t just mean adding more robots—it means orchestrating them effectively. Many teams struggle with:

- Manual task assignments, leading to inefficiencies

- Lack of automated coordination across different robotic systems

- Difficulty scaling workflows as automation grows

What You Can Do: Operational teams should embrace adaptive workflow automation, allowing their robotic fleets to dynamically adjust based on real-time operational conditions.

3. Poor Integration is Stifling Scalability

A multi-vendor approach offers flexibility, but it can also create interoperability nightmares if not managed correctly. Organizations often face:

- Incompatible communication protocols between different robots

- Custom software development bottlenecks

- Reliance on vendor-specific control panels rather than a single, unified interface

What You Can Do: Standardizing robotic system integration through open APIs and centralized fleet control can eliminate friction and future-proof automation strategies.

Looking ahead: How industry leaders are solving these challenges

Understanding the obstacles in multi-vendor robotics management is just the first step. In Part 2 of this series, we’ll explore proven solutions and strategies that leading organizations are using to simplify operations, maximize efficiency, and unlock the full potential of their robotics investments.

Ready to take control of your multi-vendor robot fleet? Reach out to Formant to talk with our team and see how we can help you scale smarter, not harder.

Stay tuned for Part 2, where we’ll break down the playbook for seamless robotics management.