As a robot fleet expands, the inevitable question looms: do you build a custom management solution or rely on a proven platform to keep everything running smoothly?

Companies often find themselves struggling to build and maintain their own cloud robotics infrastructure, sorting through data silos, and resolving errors manually. This approach may seem cost-effective initially, but it comes with significant hidden costs and challenges that can hinder your business growth.

Let’s explore the build vs buy discussion around robot management platforms, and what might be the best solution to help transform your operations.

The illusion of cost-effectiveness

At first glance, building an in-house solution appears cheaper. There’s no significant upfront investment for licensing or subscribing to an external platform. However, this short-term thinking often leads to long-term pain.

The true cost of a DIY approach extends far beyond the initial development phase. You’ll need to hire a dedicated team of DevOps engineers, full-stack developers, and data engineers. As your robot fleet grows, so does the complexity of your infrastructure, requiring more resources to maintain and scale.

Consider this: setting up basic cloud infrastructure might cost you $100K-$250K per year for a single DevOps engineer. As you build out your data pipeline, you’re looking at $500K-$700K annually for a full-stack and data engineering team. Once you’re in production, managing a team of senior data engineers, DevOps, and web developers could set you back $1.5M-$2M per year.

And that’s just the beginning. As you scale from 3 robots to 30 or more, your infrastructure needs will grow exponentially, demanding even more resources and expertise.

The complexity conundrum

Building a robust robot management platform isn’t just about writing code. It involves creating a scalable cloud infrastructure, developing real-time data ingestion systems, implementing analytics capabilities, and ensuring seamless integrations with existing tools and workflows.

Many companies underestimate the complexity of this task. They end up with a patchwork of tools that don’t integrate well, are difficult to maintain, and become increasingly unruly as the robot fleet grows. This fragmented approach often stems from a lack of foresight, where short-term needs take priority over long-term scalability.

Moreover, as your business evolves, so do your requirements. Your DIY solution might struggle to keep up with changing needs, forcing you to constantly revamp and expand your system. This cycle of continuous development and maintenance can become a significant drain on your resources.

Distracting from your core competencies

Perhaps the most overlooked cost of building your own robot management platform is the opportunity cost. Every hour your team spends on developing and maintaining this infrastructure is an hour not spent on your core business – innovating your robotics technology, improving your products, or serving your customers.

For robotics companies, your expertise lies in creating efficient, effective robots – not in building cloud platforms. By trying to do both, you risk spreading your resources too thin and potentially compromising the quality of your primary offering.

The alternative? A dedicated robot management platform that handles the complexities of data ingestion, analytics, and fleet management, allowing you to focus on what you do best – enhancing the overall performance of a fleet and keeping customers satisfied.

Scaling challenges

As your robot fleet grows, so do the challenges of managing it effectively. A DIY solution that works well for a handful of robots might buckle under the pressure when you scale to dozens or hundreds of units.

Scaling isn’t just about handling more data. It involves managing multiple deployments across different locations, integrating with various systems, and providing real-time insights across your entire fleet. These challenges require sophisticated solutions that are often beyond the scope of an in-house developed system.

A purpose-built robot management platform is designed to scale seamlessly, handling the complexities of fleet growth without requiring a proportional increase in your IT resources.

Future-proofing your operations

The robotics industry moves fast, with new competitors and use cases emerging regularly. An in-house solution will struggle to keep pace with these changes, potentially leaving you at a competitive disadvantage.

Investing in a dedicated robot management platform ensures you’re always at the forefront of technology and always up-to-date with the latest advancements to ensure every fleet operates to the highest standard of efficiency. These platforms are continuously updated and improved, incorporating the latest advancements in cloud computing, data analytics, and robotics management.

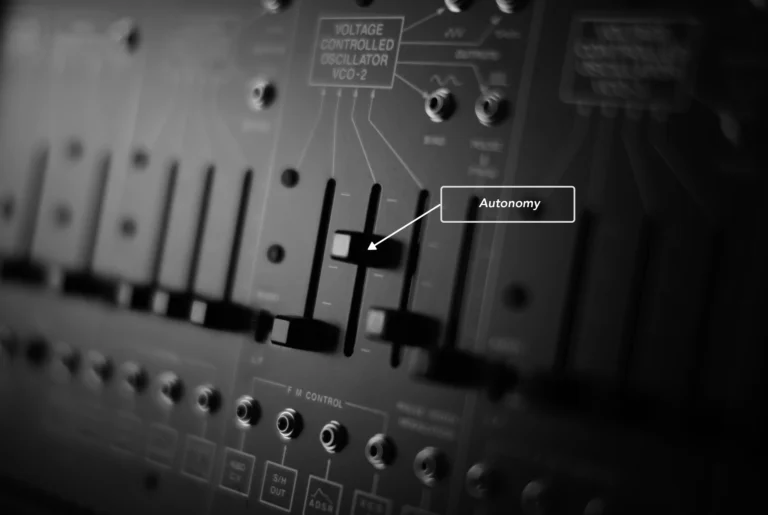

Ultimately, the choice comes down to focus. Do you want your team consumed by infrastructure challenges, or empowered to push the boundaries of robotics innovation? While building your own robot management solution might seem attractive initially, the hidden costs in terms of resources, complexity, and missed opportunities often outweigh the perceived benefits. By opting for a dedicated platform, you can focus on your core competencies, scale your operations efficiently, and stay ahead in the competitive robotics landscape.

Remember, your value lies in the robots you build and the problems they solve, not in the infrastructure that manages them. Choose wisely, and let your robots – not your IT challenges – define your success.

By leveraging existing platforms, companies can accelerate deployments, future-proof their tech stack, and keep their attention where it belongs – on their core mission and customers.

To learn more about Formant’s cloud robotics solution, request a demo with our team.